Reinventing the design process, ensuring success

05.02.20The best buildings and infrastructure in history are the result of high degrees of consistency at all levels of their realisation. This occurs when all members of the design team are working toward the same objectives.

The way our industry operates differs significantly from many others. Traditionally, we split the designer from close integration with, and responsibility for, delivering the vision and overcoming the inevitable manufacturing and construction challenges. Society reinforces this stereotype, imagining architects as being a world away from the muddy boots of construction.

Today’s designers have to influence and integrate an increasing range of information to create an elegant, useful and durable whole. Meanwhile, clients rightly demand greater value from their investments. New and increasing technical requirements necessitate the coordination of ever wider skill sets.

Clearly, successful delivery of these projects is more than one individual can achieve based on one set of perspectives and experience.

Laing O’Rourke is promoting an alternative approach. Our continuous evolution as an engineering enterprise allows us to work as a delivery partner alongside our clients and their teams from the outset of their projects to overcome the challenges of realising their vision.

So, how does Laing O’Rourke’s early engagement in the design process enable the team to deliver this industry-changing outcome? How can technology-driven collaborative design achieve certainty of success?

The current risks for clients: Uncertainty of outcomes

A key barrier to improved efficiency and added value in the construction sector is the disconnection that traditional procurement causes between the design community, led by architects and consulting engineers, and the delivery community of contractors and their supply chains.

At the start of a project, a client’s first step is often to commission their chosen architect to develop a brief and produce ‘concepts’ that start to define what will be needed. The best of these concepts are then developed by the architect and consulting engineers into a detailed design that any contractor team can tender for.

These ‘agnostic’ designs are too often created with little insight into how the project will actually be delivered, and avoid specific construction products or processes that could contribute significant improvements. They often adopt approaches that are lowest common denominators so that designs are within the capabilities of all tenderers and remain open to competition. At the end of the process, too many clients select the winning tender with the lowest submitted cost without sufficient understanding of what might follow.

This traditional procurement route excludes the delivery team from the early creative process and lacks input from the people who best understand the risks and opportunities that lie ahead during the manufacture and construction of the project.

As a result it leaves clients with the risk that they will become exposed to budget over-runs, schedule problems, and disappointments as the difficulties of realising the original design intent are encountered on site, often way too late in the process to react in a smart way.

No one wins in these situations. The architects and engineers are frequently called upon to produce rushed re-designs to solve unexpected problems, and clients are not always happy to pay for this work. The design team can become frustrated as the clarity and efficiency of the original design intent becomes diluted in a scramble to re-design, a process often and inappropriately badged as value-engineering when it is anything but. Meanwhile, the delivery team has its work complicated by late information and changes allowing little opportunity for it to contribute its ideas.

At handover, clients can too often end up with a building or facility that does not perform as required, exceeds the budget, or is not ready on time − or perhaps all three. This can result in the relationships and reputations of all those involved suffering great damage.

This is an all too familiar story; time and again we see projects follow this path and it is no wonder that the reputation of the construction industry to deliver what it says it will is regarded as patchy at best.

The way forward: Early engagement

At Laing O’Rourke, we see the key to overcoming these issues is through early engagement and partnership between the clients, designers, and deliverers of construction projects. This has in part been adopted across the civil engineering sector but now construction companies need to play an integral, proactive role in the design development of projects from the earliest stage, rather than reacting to it later on.

By influencing the design of a client’s project to maximise the benefits from construction expertise, quality can be improved and programme reduced. Time saved over traditional processes and through faster delivery can in part be reallocated upfront to the design phase which can help ensure that completed designs are defect-free, fully coordinated and are not revisited to recover things late in the day. This still leaves space for schedule savings to be enjoyed by the client or end-users.

An integrated design process also includes the participation of users and regulatory authorities as well as building technologists, subcontractors, cost consultants, civil, structural, mechanical and electrical engineers, specifications experts, and consultants from many other specialised fields. The best project outcomes result from continuing, organised collaboration among all parties throughout the project’s lifecycle.

Laing O’Rourke has recast the design process, moving to technology-driven collaboration between the client, designers and delivery partner at the very beginning of a project. Such early collaboration delivers the benefits previously described and enables the project team to embrace Laing O’Rourke’s manufacturing-led construction approaches, resulting in optimum use of design time, reduced risk and maximum value. By re-ordering the activities that each party carries out – developing and then locking down the design in the best sequence, agreeing manufacturing and construction processes up front – greater value will be unlocked for the client and we can deliver significantly improved certainty.

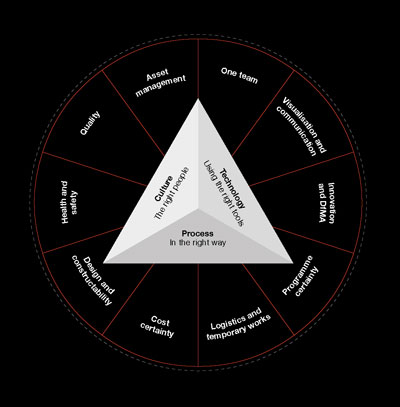

The aim is to mesh good quality design with practical buildability and our unique and innovative delivery methodologies. This is enabled through Laing O’Rourke’s operating model, a combination of: excellence in engineering; digital engineering; Design for Manufacture and Assembly (DfMA) and offsite manufacturing; and direct delivery. Early engagement and collaborative working, as a true delivery partner, is the only way to genuinely ensure that the value of initial design is actually delivered in the finished product.

Many clients already understand and embrace our approach, and – despite some areas of traditional reticence – increasingly so do many architectural and consulting engineering design practices. They recognise that this collaboration can deliver outcomes far removed from their previous poor experiences with traditional design-build approaches.

Laing O’Rourke’s engagement now extends from the initial concept stage through design development, construction and manufacture, soft landing and, increasingly, into operation, decommissioning and re-use: a true end-to-end engineering-led approach.

Our early engagement focuses input on a number of strategic areas in support of the overall design intent and process. But the primary emphasis is on maximising value-based DfMA solutions using a digital environment. The integrated design and delivery team can then work together to increase speed and quality of construction by adopting manufactured and preassembly methods, which can be planned and scheduled in parallel with other onsite activities.

The advantages of DfMA and in adopting a more manufactured approach to construction are numerous, including better quality and value, greater certainty of delivery, fewer people on site, safer and cleaner working environments, less noise and waste, and overall shorter construction times. Offsite manufactured bathrooms and plant rooms are commissioned before they arrive on site. Superior concrete products have precisely placed reinforcement and embedments and improved dimensional and quality control. Above all a manufactured approach can deliver as technically perfect a set of components and buildings as is possible with a finish and feel that is all but impossible using traditional onsite techniques.

Laing O’Rourke’s early involvement in a project also opens up a range of exciting and innovative new manufacturing opportunities that design teams can access ahead of the pack. As manufacturing technology improves, so does the flexibility to deliver more bespoke products and assemblies. Through parametric design models, complex engineered units such as plant rooms can be scaled up or down to meet a building’s operational requirements and then manufactured in a fraction of the time to greater accuracy and quality.

Collaboration not competition

Constructors should not be seen as a commercial threat to their design partners. The design process is an opportunity for the delivery team to collaborate with architectural and engineering consultancies rather than compete with them, and to do so right from the outset. At Laing O’Rourke, we understand the value of great design by great designers; working alongside the architects and consulting engineers, we protect the ‘joy’ of design, encouraging the best ideas, stimulating others, but at each step ensuring that what we dream up together is not only deliverable but is deliverable in as smart a way as is possible.

Without early engagement, a contractor cannot bring its engineering ‘smarts’ fully into play. On the other hand, it is important that a contractor’s products and processes should not be forced on design partners as a fait accompli. The key is to adopt design collaboration within simple design protocols that lead to better construction and certainty; designs that unlock greater value. A manufacturing-led approach requires constructors to take their clients and project teams through a unique process on their projects. For instance, room layouts must be considered much sooner in the design process, right down to where the light switches and plug sockets go. That allows walls to be manufactured off site, with all the services in the right place, before assembly on site, eliminating the often disruptive rework of conventional construction.

This doesn’t work everywhere as there is no one-size-fits-all approach, but the knowledge of the constructor in enabling this whole collaborative process in a new and exciting direction is essential.

This can be a win-win situation for architects and consulting engineers as it minimises downstream problems in manufacture and construction, and ensures a better result for − and therefore a more sustainable relationship with − their clients too.

As part of the collaborative team an engineering enterprise can enhance the design process, protect design integrity, minimise the risk and unlock greater value − both for the client and for the project team as a whole.

Founded on digital engineering

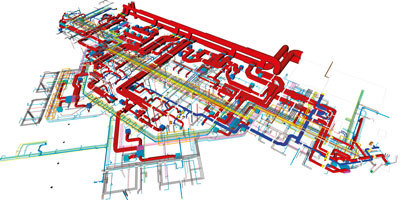

A key enabler of this new approach to collaborative working is digital engineering, which underpins the entire end-to-end delivery process − from design through to construction, commissioning, operation and beyond. Creating a digital platform at the outset of a project allows a virtual prototype to be built, which becomes central to the work of all members of the design team. Validation of the design and build elements of a project in the virtual world provides greater certainty of outcomes in critical areas like cost, programme and quality. It also allows the architects, design consultants and delivery partner to work in a coordinated model environment, helping to improve the design integration and reducing the risks normally associated with the discipline interfaces.

Laing O’Rourke’s early management of the federated digital model facilitates informed decision-making by demonstrating the impacts of change much quicker, so helping to build a complete understanding amongst all the design stakeholders. It streamlines the approvals process, helping to achieve greater buy-in to the project in the delivery phase. The digital model also allows early delivery of construction work-packs, providing onsite and factory operatives with easily accessible, accurate, real-time data, supporting better planning of delivery on site and driving up productivity. We connect design to construction digitally as we know from our experiences that this is the best way to improve certainty of outcomes.

Conclusions

Clients and society need the construction industry to challenge the conventional design and procurement process. Through collaborative partnerships formed at the beginning of a project, design and delivery teams can adopt a new approach to design that unlocks greater value in every sense: in the quality of the design, in the quality of the delivery and in the quality of the end product.

Laing O’Rourke’s development as a fully fledged engineering enterprise allows us to work with designers to deliver our clients’ visions with increased certainty of success. Working collaboratively as a delivery partner from the earliest project stages, we assure the quality, cost and programme outcomes that are vital to success.

As an integral part of the project team, we make sure the needed experience of construction, manufacturing and logistics, available in our direct delivery teams, is embodied in the design vision from its earliest development. We enable the design team to develop a DfMA and manufacturing-led strategy that delivers the project certainty, without forcing it onto projects in a clumsy way. Our digital engineering strategy ensures effective information flow from designer, to manufacture, to site, and then on into operation. Through excellence in engineering we bring the vital technical skills needed that turn a vision into a reality.

At Laing O’Rourke we continue to deliver our clients’ compelling design visions, but now with unparalleled certainty though our unique operating model. By engaging early with a delivery partner, with a fully collaborative open-book approach to managing costs and risks, clients and their design teams can avoid the traps of traditional lowest-cost procurement, the project team is able to focus on the key delivery issues up front, innovation and collaboration drive the process end-to-end, and agnostic designs of limited value can finally be consigned to history.

This article has been updated since its original publication in 2015.

Download this article as a PDF by clicking on the link below

- Icon pdf Reinventing Pdf